Process and Analytical Development

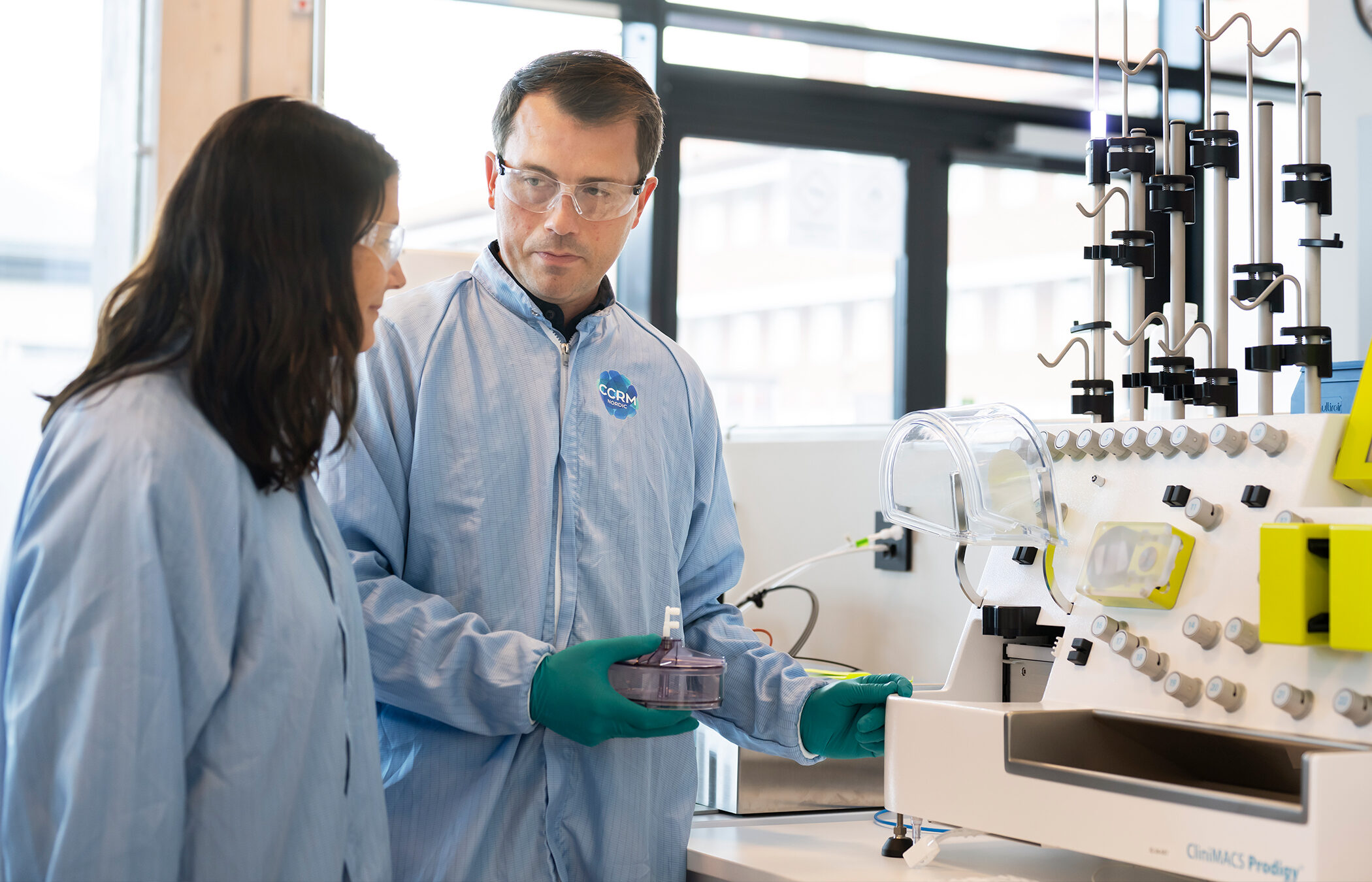

We develop reproducible, scalable, and GMP-compliant manufacturing processes and analytics for your ATMP. Our work provides a robust foundation for your therapy, ensuring a cost-effective and viable path to the clinic and market.

- Viral- and cell-based therapies

- Upstream, downstream, and analytical development

- Scale-up, GMP translation, and tech transfer

Let's discuss how we can future-proof your analytics and process!

P&AD: The Foundation for Market-Viable ATMPs

Our process and analytical development services are designed to address the critical demands of your specific ATMP program. We support you in building a reproducible and cost-effective manufacturing process with robust analytics, ensuring you can manage product variability, guarantee patient safety and efficacy, satisfy regulatory requirements, and enable a scalable path to commercial production.

We’ve set up our immune cell therapy workflows and generated some interesting data we’re happy to share with you in a poster. Reach out to us if you’d like to hear more about the cost of manufacturing comparisons we’ve done for the featured platforms.

How We Support Your Development Journey

We support ATMP developers at all lifecycle stages, from initial protocol development to post-launch manufacturing changes. Our work is performed in our development labs, with a focus on seamless future technology transfer to our own, or a selected CMO’s GMP manufacturing suite. If required, we can incorporate Quality by Design (QbD) to generate a complete CMC package. See our CMC Support page for more information.

Flexible Project Scope

We can assist with individual unit operations and analytical methods or develop end-to-end manufacturing processes with all associated analytics.

Platform Expertise

While we work with all ATMP types, we have established a platform for immune cell therapies and are building platforms for lentiviral vector production and iPSC-derived cell therapies.

Agile Partnership

Our services are offered on a fee-for-service basis. In cases of a strong strategic fit, such as incubation, services may be provided in-kind.

Our Labs and Future Capabilities

Our first development lab is fully operational today. By mid 2026, we will move into our new, 1000 m2 purpose-built development labs. This new facility will be adjacent to our GMP manufacturing site, making future tech transfer as simple as possible. We are already supporting projects that are moving towards clinical supply from our future GMP facility.

-

Existing Capabilities

Our current, fully functional lab is equipped to support your process and analytical development needs today.

-

Increased Future Capacity (H2 2027)

Our new, larger labs will allow us to take on more projects concurrently and work at larger bioreactor scales.

-

Seamless GMP Translation

The co-location of our future development and GMP manufacturing facilities will ensure the most efficient tech transfer possible.

Case studies

Stay Connected with CCRM Nordic

Join our network for exclusive insights, career opportunities, and thought leadership content from Nordic industry experts.

- 4000+ professionals

- Direct communication

- Weekly insights

Discover Our Other Areas of Support

-

GMP Manufacturing

Early-stage GMP supply for viral and cell therapies, ready by H2 2027.

Read more -

Analytical Services

Safety, identity, and molecular testing to support reliable ATMP development.

Read more -

Market and IP Services

Market and IP services to secure strategy and prepare ATMPs for commercialization.

Read more